User Guide - Eurotherm Ltda

User Guide - Eurotherm Ltda

User Guide - Eurotherm Ltda

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

nanodac<strong>User</strong> <strong>Guide</strong>nanodac recorder/controllerVersions 5.00 and laterHA030554/7November 2012

© 2012 <strong>Eurotherm</strong> LimitedAll rights are strictly reserved. No part of this document may be reproduced, modified, or transmittedin any form by any means, nor may it be stored in a retrieval system other than for the purposeto act as an aid in operating the equipment to which the document relates, without the prior, writtenpermission of <strong>Eurotherm</strong> Limited.<strong>Eurotherm</strong> Limited pursues a policy of continuous development and product improvement. Thespecification in this document may therefore be changed without notice. The information in thisdocument is given in good faith, but is intended for guidance only. <strong>Eurotherm</strong> Limited will acceptno responsibility for any losses arising from errors in this document.

Declaration of ConformityManufacturer's name:Manufacturer's address:Product type:Models:<strong>Eurotherm</strong> LimitedFaraday Close, Worthing, West Sussex,BN13 3PL, United KingdomRecorder / controllernanodac Status level A1 and aboveSafety specification: EN61010-1: 2001EMC emissions specification: EN61326-1: 2006 Class B (100 to 230V ac supply)EN61326-1: 2006 Class A (24V ac/dc supply)EMC immunity specification:EN61326-1: 2006 Industrial locations<strong>Eurotherm</strong> Limited hereby declares that the above products conform to the safety andEMC specifications listed. <strong>Eurotherm</strong> Limited further declares that the above productscomply with the EMC Directive 2004/108/EC, and also with the Low Voltage Directive2006/95/EC.Signed:Dated:Signed for and on behalf of <strong>Eurotherm</strong> Limited.Kevin Shaw(R&D Director)IA249986U790 Issue 2 Oct 10 (CN26774)

nanodac RECORDER/CONTROLLER: USER GUIDEnanodac Recorder/Controller<strong>User</strong> <strong>Guide</strong>List of sectionsSectionPage1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 565 Modbus TCP slave comms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1706 iTools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2577 <strong>User</strong> Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2878 USB Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 292A Technical specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293B Control Loops . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299C Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 327D Configuration menu overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 335E Web Server. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 351F Labview Driver. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 361Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 367Associated documentsHA028838 Printable version of iTools HelpHA025464 EMC installation guidelinesHA027962 Printable version of ‘Review’ HelpApplication notesHA030817U001 Archiving data from the nanodac recorder/controllerHA030817U002 Heat/Cool with carbon potential or oxygen level monitoringHA030817U003 Heat only temperature control and carbon potential controlHA030817U004 Virtual channels using the nanodac recorder/controller.Software effectivityThis manual refers to instruments fitted with software version 5.0.Software versions 2.20 onwards are ‘backwards compatible’ so that it can be used onall hardware versions of the unit.Previous software versions are not compatible with instruments with hardware statusgreater than 2.The status level may be found on the instrument label and consists of a letter indicatingsoftware status followed by a numeral indicating the hardware status (e.g. ‘B2’)HA030554Issue 7 Nov 12Page i

nanodac RECORDER/CONTROLLER: USER GUIDEnanodac Recorder/Controller<strong>User</strong> <strong>Guide</strong>Contents ListSection1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31.1 UNPACKING THE INSTRUMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32.1 MECHANICAL INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32.1.1 Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32.1.2 Demounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32.2 ELECTRICAL INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52.2.1 Termination details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52.2.2 Low Voltage Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72.2.3 Dual Input Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72.2.4 Modbus Master communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72.2.5 EtherNet/IP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73 OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83.1.1 Display Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83.1.2 Navigation Pushbuttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83.1.3 On Screen Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93.2 PROCESS VARIABLE DISPLAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103.2.1 Alarm Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103.2.2 Status Bar Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113.2.3 Breaks in recording . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133.3 TOP LEVEL MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143.3.1 Home . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143.3.2 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143.3.3 Go to View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153.3.4 History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183.3.5 Faceplate Cycling on/off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183.3.6 Operator Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183.3.7 Demand Archiving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183.3.8 Login . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203.4 DISPLAY MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223.4.1 Vertical Trend . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223.4.2 Horizontal Trend mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233.4.3 Vertical Bargraph mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233.4.4 Horizontal Bargraph mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243.4.5 Numeric mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243.4.6 Alarm panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253.4.7 Control Loop1/Loop2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263.4.8 Cascade Display Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273.4.9 Programmer Display Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283.4.10 Steriliser display mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 403.4.11 Promote list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 443.4.12 Modbus Master display mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 453.4.13 EtherNet/IP display mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 473.5 TREND HISTORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 533.5.1 Navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 533.5.2 History Options Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 543.6 TEXT ENTRY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 553.6.1 Numeric keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 553.6.2 USB keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 554 CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .564.1 INSTRUMENT MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 574.1.1 Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58Page iiHA030554Issue 7 Nov 12

nanodac RECORDER/CONTROLLER: USER GUIDEList of Contents (Cont.)SectionPage4.1.2 Locale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 594.1.3 Display configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 604.1.4 Info menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 624.1.5 Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 634.1.6 Security menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 644.1.7 I/O fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 664.1.8 Save/Restore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 674.1.9 Input adjust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 684.1.10 Output adjust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 714.2 NETWORK MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 724.2.1 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 724.2.2 Archiving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 734.2.3 FTP Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 754.2.4 Modbus TCP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 764.3 GROUP CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 774.3.1 Group Trend configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 774.3.2 Group Recording configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 784.4 INPUT CHANNEL CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 794.4.1 Channel Main . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 804.4.2 Channel Trend configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 844.4.3 Alarm 1 menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 854.4.4 Alarm 2 menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 864.4.5 Alarm types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 874.5 VIRTUAL CHANNEL CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 894.5.1 Maths channel configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 894.5.2 Totaliser configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 914.5.3 Wiring Example using a counter in combination with a totaliser . . . . . 954.5.4 Counter configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 964.6 LOOP OPTION CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 984.6.1 Main menu parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 994.6.2 Setup menu parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 994.6.3 Tune menu parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1004.6.4 PID menu parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1014.6.5 Setpoint menu parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1024.6.6 Output menu items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1034.6.7 Loop diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1054.7 ADVANCED LOOP CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1064.7.1 Advanced Loop Main menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1074.7.2 Advanced Loop Setup menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1084.7.3 Advanced Loop Tune menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1094.7.4 Advanced Loop Master PID menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1134.7.5 Advanced Loop Slave PID menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1144.7.6 Advanced Loop Master SP menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1164.7.7 Advanced Loop Slave SP menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1184.7.8 Advanced Loop Output menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1204.7.9 Advanced Loop Diagnostics menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1234.8 PROGRAMMER CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1244.8.1 Programmer Features menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1254.8.2 Programmer FTP menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1274.8.3 Programmer Setup menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1284.8.4 Programmer Run menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1314.8.5 Connecting the programmer to a loop . . . . . . . . . . . . . . . . . . . . . . . . . . 1334.8.6 Configuration by Modbus Comms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1354.9 MODBUS MASTER CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1364.9.1 Slave Main menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1374.9.2 Slave Diagnostics menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1384.9.3 Modbus master data configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1394.10 ETHERNET/IP CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1424.10.1 Ethernet/IP Configuration Main menu . . . . . . . . . . . . . . . . . . . . . . . . . . . 1424.10.2 Implicit inputs/outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1434.10.3 Explicit inputs/outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1434.11 WEB SERVER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1454.11.1 Configuration Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145HA030554Issue 7 Nov 12Page iii

nanodac RECORDER/CONTROLLER: USER GUIDEList of Contents (Cont.)SectionPage4.12 DIGITAL I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1464.12.1 Digital input/output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1464.12.2 Relay outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1464.12.3 Digital inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1474.12.4 Digital outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1474.13 DC OUTPUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1484.13.1 Configuration display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1484.14 USER LIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1494.14.1 <strong>User</strong> linearisation table rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1494.15 CUSTOM MESSAGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1494.16 ZIRCONIA BLOCK OPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1504.16.1 Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1504.16.2 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1514.16.3 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1544.17 STERILISER OPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1554.17.1 Configuration parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1554.18 HUMIDITY BLOCK OPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1574.18.1 Configuration parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1574.19 BCD INPUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1584.19.1 Input rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1584.19.2 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1584.20 LOGIC (2 INPUT) BLOCK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1594.20.1 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1594.21 LOGIC (8 INPUT) BLOCK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1604.21.1 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1604.21.2 Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1604.21.3 Invert input decoding table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1614.22 Multiplexer block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1624.22.1 Configuration parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1624.23 MATH (2 INPUT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1634.23.1 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1634.23.2 Sample and Hold details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1644.24 TIMER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1654.24.1 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1654.24.2 Timer modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1654.25 USER VALUES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1674.25.1 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1674.26 ALARM SUMMARY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1684.27 REAL TIME EVENT CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1695 MODBUS TCP SLAVE COMMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1705.1 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1705.2 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1705.2.1 Function Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1705.2.2 Data types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1715.2.3 Invalid multiple register writes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1715.2.4 Master communications timeout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1715.2.5 Non-volatile parameters in EEPROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1725.3 PARAMETER LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1756 iTOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2576.1 iTools CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2586.1.1 Ethernet (Modbus TCP) communications . . . . . . . . . . . . . . . . . . . . . . . . . 2586.1.2 Direct Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2606.2 SCANNING FOR INSTRUMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2616.3 GRAPHICAL WIRING EDITOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2626.3.1 Tool bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2636.3.2 Wiring editor operating details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2636.4 PARAMETER EXPLORER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2716.4.1 Parameter explorer detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2726.4.2 Explorer tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273Page ivHA030554Issue 7 Nov 12

nanodac RECORDER/CONTROLLER: USER GUIDEList of Contents (Cont.)SectionPage6.4.3 Context Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2736.5 WATCH/RECIPE EDITOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2746.5.1 Creating a Watch List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2746.5.2 Watch Recipe toolbar icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2756.5.3 Watch/Recipe Context Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2756.6 PROGRAMMER OPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2766.6.1 Segment parameter editing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2766.6.2 Digital Event display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2786.6.3 Program parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2786.6.4 Adding and deleting segments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2796.6.5 Loading and Saving programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2806.6.6 Toolbar icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2806.6.7 Context menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2816.6.8 Programmer menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2826.6.9 Two channel programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2836.6.10 To Set Up OEM Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2847 USER WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2877.1 DRIVE RELAY EXAMPLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2877.1.1 Wire removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2887.2 COUNTER EXAMPLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2898 USB DEVICES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2928.1 MEMORY STICK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2928.2 BAR CODE READER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2928.3 USB KEYBOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 292Appendix A: TECHNICAL SPECIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293A1 INSTALLATION CATEGORY AND POLLUTION DEGREE . . . . . . . . . . . . . . . . . . . . 293Installation category II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293Pollution degree 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293A2 RECORDER SPECIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 294A3 ANALOGUE INPUT SPECIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295A4 RELAY AND LOGIC I/O SPECIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297A5 DIGITAL INPUTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297A6 DC OUTPUTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297A7 BLOCKS SUPPORTED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297A7.1 ‘TOOLKIT’ BLOCKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297A7.2 APPLICATION BLOCKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 298Appendix B CONTROL LOOPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299B.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299B1.1 EXAMPLE (HEAT ONLY) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299B2 CONTROL LOOP DEFINITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299B2.1 AUTO/MANUAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299B2.2 TYPES OF CONTROL LOOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300B2.2.1 On/Off control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300B2.2.2 PID Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300PROPORTIONAL BAND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300INTEGRAL TERM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301DERIVATIVE TERM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301B2.2.3 Motorised valve control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 302MANUAL MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 302MOTORISED VALVE OUTPUT CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . 302B2.3 LOOP PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303B2.3.1 Relative cool gain (R2G) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303B2.3.2 High and Low cutback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303B2.3.3 Manual Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303B2.3.4 Integral Hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304B2.3.5 Integral De-bump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304HA030554Issue 7 Nov 12Page v

nanodac RECORDER/CONTROLLER: USER GUIDEList of Contents (Cont.)SectionPageB2.3.6 Loop Break . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304B2.3.7 Gain Scheduling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305B2.4 TUNING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305B2.4.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305B2.4.2 Loop Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306UNDER DAMPED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306CRITICALLY DAMPED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306OVER DAMPED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306B2.4.3 Initial Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306SETPOINT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306OUTPUT HIGH, OUTPUT LOW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306REM. OUTPUT LOW, REM. OUTPUT HIGH . . . . . . . . . . . . . . . . . . . . . . . . . . . 306Ch2 DeadBand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306MINIMUM ON TIME . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306FILTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306RATE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307CH1 TRAVEL TIME, CH2 TRAVEL TIME . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307B2.4.4 Other tuning considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307B2.4.5 Autotune . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307AUTOTUNE AND SENSOR BREAK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308AUTOTUNE AND INHIBIT OR MANUAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308AUTOTUNE AND GAIN SCHEDULING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308INITIAL CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308INITIATING THE AUTOTUNE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308EXAMPLE 1: AUTOTUNE FROM BELOW SP (HEAT/COOL) . . . . . . . . . . . 309EXAMPLE 2: AUTOTUNE FROM BELOW SP (HEAT ONLY) . . . . . . . . . . . . 310EXAMPLE 3: AUTOTUNE AT SP (HEAT /COOL) . . . . . . . . . . . . . . . . . . . . . . 311AT.R2G . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 312FAILURE MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 313B2.4.6 Relative Cool Gain in Well Lagged Processes . . . . . . . . . . . . . . . . . . . . 313EXAMPLE 4: When Tune R2G = R2GPD, Autotune from below setpoint 314B2.4.7 Manual tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 314CUTBACK VALUES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 315B2.5 SETPOINT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 316B2.5.1 Setpoint function block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 316B2.5.2 Setpoint Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 318B2.5.3 Setpoint Rate Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 318B2.5.4 Setpoint Tracking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 319B2.5.5 Manual Tracking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 319B2.6 OUTPUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 320B2.6.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 320B2.6.2 Output Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 320B2.6.3 Output Rate Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 321B2.6.4 Sensor Break Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 321SAFE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 321HOLD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 321B2.6.5 Forced Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 321B2.6.6 Power Feed Forward . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 322B2.6.7 Cool Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 322LINEAR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 322OIL COOLING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 322WATER COOLING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 322FAN COOLING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 322B2.6.8 Feed forward . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 323B2.6.9 Effect of Control Action, Hysteresis and Deadband . . . . . . . . . . . . . . 323CONTROL ACTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 323HYSTERESIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 323DEADBAND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 323B2.6.10 Valve nudge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 325B2.6.11 Time Proportioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 326B2.7 DIAGNOSTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 326Appendix C: REFERENCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 327C1 BATTERY REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 327Page viHA030554Issue 7 Nov 12

nanodac RECORDER/CONTROLLER: USER GUIDEList of Contents (Cont.)SectionPageC2 SETTING UP AN FTP SERVER USING FILEZILLA . . . . . . . . . . . . . . . . . . . . . . . . . . . . 328C2.1 DOWNLOADING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 328C2.2 SERVER SETUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 330C2.3 PC SETUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 331C2.4 RECORDER/CONTROLLER SET UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 331C2.5 ARCHIVE ACTIVITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 332C3 FUNCTION BLOCK DETAILS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 333C3.1 EIGHT INPUT OR BLOCK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 333C4 TCP PORT NUMBERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 334C5 ISOLATION DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 334Appendix D: CONFIGURATION MENU OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . 335D1 INSTRUMENT CONFIGURATION MENUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 336D2 NETWORK CONFIGURATION MENUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 337D3 GROUP CONFIGURATION MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 338D4 CHANNEL CONFIGURATION MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 338D5 VIRTUAL CHANNEL CONFIGURATION MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 339D6 LOOP CONFIGURATION MENUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 340D7 ADVANCED LOOP CONFIGURATION MENUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 341D8 PROGRAMMER CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 343D9 MODBUS MASTER CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 344D10 ETHERNET/IP CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 345D11 DIGITAL I/O CONFIGURATION MENUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 346D12 DC OUTPUT CONFIGURATION MENUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 346D13 USER LINEARISATION TABLE CONFIGURATION MENU . . . . . . . . . . . . . . . . . . 346D14 CUSTOM MESSAGES CONFIGURATION MENU . . . . . . . . . . . . . . . . . . . . . . . . . . 346D15 ZIRCONIA BLOCK CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 347D16 STERILISER BLOCK CONFIGURATION MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . 348D17 HUMIDITY BLOCK CONFIGURATION MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 348D18 BCD INPUT BLOCK CONFIGURATION MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . 348D19 LOGIC (2 INPUT) CONFIGURATION MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 349D20 LOGIC (8 INPUT) CONFIGURATION MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 349D21 MULTIPLEXER BLOCK CONFIGURATION MENU . . . . . . . . . . . . . . . . . . . . . . . . . 349D22 MATH (2 INPUT) CONFIGURATION MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 349D23 TIMER CONFIGURATION MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 350D24 USER VALUES CONFIGURATION MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 350E Appendix E: WEB SERVER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .351E.1 Browsers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 351E.1.1 Connecting to the Internet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 351E.1.2 Denied Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 351E.2 Error Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 351E.2.1 Home Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 352E.2.2 About Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 352E.2.3 Contact Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 353E.2.4 Bar Graph Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 354E.2.5 Line Graph Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 355E.2.6 Numeric Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 356E.2.7 Alarm Summary Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 356E.2.8 Message Summary Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 357E.2.9 Promote Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 357E.2.10 Historical Line Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 358E.2.11 Status Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 359E.2.12 DHCP Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 359HA030554Issue 7 Nov 12Page vii

nanodac RECORDER/CONTROLLER: USER GUIDEList of Contents (Cont.)SectionPageE.2.13 Network Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 359E.2.14 Languages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 359F Appendix F: Labview Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .361F.1 Application Example 1 - Heat/Cool Control . . . . . . . . . . . . . . . . . . . . . . . . . . . 361F.2 Application Example 2 - Program Load by Program Number . . . . . . . . . . . . 364F.3 Application Example 3 Steriliser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 365F.4 Application Example 4 Configurable Steriliser . . . . . . . . . . . . . . . . . . . . . . . . 365F.5 Full driver capabilities list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 366Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 367Page viiiHA030554Issue 7 Nov 12

nanodac RECORDER/CONTROLLER: USER GUIDESAFETY NOTESWARNINGS1. Any interruption of the protective conductor inside or outside the apparatus, or disconnection ofthe protective earth terminal is likely to make the apparatus dangerous under some fault conditions.Intentional interruption is prohibited.2. Live sensors: The unit is designed to operate if the temperature sensor is connected directly toan electrical heating element. It must be ensured that service personnel do not touch connectionsto such inputs whilst the inputs are live. With live sensors, all cables, connections and switchesfor connecting the sensor must be mains rated for use in 240V Cat II.3. Grounding the temperature sensor shield: Where it is common practice to replace the temperaturesensor whilst the instrument is live, it is recommended that the shield of the temperature sensorbe grounded to safety earth, as an additional protection against electric shock.4. The instrument must not be wired to a three-phase supply with an unearthed star connection, because,under fault conditions, such a supply could rise above 240V RMS with respect to ground,thus rendering the instrument unsafe.Notes:1. Safety requirements for permanently connected equipment state:a. A switch or circuit breaker shall be included in the building installation.b. It shall be in close proximity to the equipment and within easy reach of the operator.c. It shall be marked as the disconnecting device for the equipment.2. Recommended external fuse ratings are: 2A Type T 250V.1. This instrument is intended for industrial temperature and process control applications within therequirements of the European directives on safety and EMC.2. Installation may be carried out only by qualified personnel.3. To prevent hands or metal tools coming into contact with parts that are electrically live the instrumentmust be installed in an enclosure.4. Where conductive pollution (e.g. condensation, carbon dust) is likely, adequate air conditioning/filtering/sealingetc. must be installed in the enclosure.5. The mains supply fuse within the power supply is not replaceable. If it is suspected that the fuse isfaulty, the manufacturer’s local service centre should be contacted for advice.6. Whenever it is likely that protection has been impaired, the unit shall be made inoperative, andsecured against accidental operation. The manufacturer’s nearest service centre should be contactedfor advice.7. If the equipment is used in a manner not specified by the manufacturer, the protection provided by theequipment might be impaired.8. The unit must be wired according to the instructions in this manual.9. Before any other connection is made, the protective earth terminal shall be connected to a protectiveconductor. The mains (supply voltage) wiring must be terminated in such a way that, should it slip, theEarth wire would be the last wire to become disconnected. The protective earth terminal must remainconnected (even if the equipment is isolated from the mains supply), if any of the I/O circuits are connectedto hazardous voltages*.The protective earth connection must always be the first to be connected and the last to be disconnected.Wiring must comply with all local wiring regulations, e.g. in the UK, the latest IEEE wiring regulations(BS7671) and in the USA, NEC class 1 wiring methods.10. Signal and supply voltage wiring should be kept separate from one another. Where this is impractical,shielded cables should be used for the signal wiring.* A full definition of ‘Hazardous’ voltages appears under ‘Hazardous live’ in BS EN61010. Briefly, under normaloperating conditions, hazardous voltages are defined as being > 30V RMS (42.2V peak) or > 60V dc.HA030554Issue 7 Nov 12Page 1

nanodac RECORDER/CONTROLLER: USER GUIDESAFETY NOTES (Cont.)11. The maximum continuous voltage applied between any of the following terminals must not exceed 240Vac.1. Relay output to logic, dc or sensor input connections2. Any connection to ground.The ac supply must not be connected to sensor input or low-level inputs or outputs.12. Over temperature protection: A separate over-temperature protection unit (with an independent temperaturesensor) should be fitted to isolate the process heating circuit should a fault condition arise.Alarm relays within the recorder/controller do not give protection under all fault conditions/13. In order to allow the power supply capacitors to discharge to a safe voltage, the supply must be disconnectedat least two minutes before the instrument is removed from its sleeve. The touching of theexposed electronics of an instrument which has been removed from its sleeve should be avoided.14. Instrument labels may be cleaned using iso-propyl alcohol, or water or water-based products. A mildsoap solution may be used to clean other exterior surfaces.USB DEVICE PRECAUTIONSNote: the use of U3 USB Flash drives is not recommended.1. Precautions against electrostatic discharge should be taken when the instrument terminals are beingaccessed. The USB and Ethernet connections are particularly vulnerable.2. Ideally, the USB device should be plugged directly into the instrument, as the use of extension leadsmay compromise the instrument’s ESD compliance. Where the instrument is being used in an electrically‘noisy’ environment however, it is recommended that the user brings the USB socket to the frontof the panel using a short extension lead. This is because the USB may ‘lock up’ or reset in noisy environmentsand the only means of recovery is to remove the device, then re-insert it. For memory sticks,EMC-related failure during a write operation might cause corruption of the data held on the stick. Forthis reason, the data on the memory stick should be backed up before insertion and checked afterremoval.3. When using a USB extension cable, a high quality screened cable must be used. The total length ofUSB cable between the device and the USB port must not exceed 3 metres (10 ft.)4. Most barcode readers and keyboards are not designed for use in industrial EMC environments, andtheir operation in such environments may result in impaired performance of the recorder/controller.32-BIT RESOLUTIONFloating point values are stored in IEEE 32-bit single precision format. Values which require greater resolutionthan is available in this format are rounded up or down.SYMBOLS USED ON THE RECORDER LABELLINGRefer to manual for instructionsThis unit is CE approvedC-Tick mark for Australia (ACA)and New Zealand (RSM)Risk of electric shockPrecautions against static electrical dischargemust be taken when handlingthis unitEthernet connectorUnderwriters laboratories listedmark for Canada and the U.S.A.USB connectorOne or more of the For symbols environmental below may reasons, appear this as unit a part of the recorderProtectivelabelling.conductive terminalmust be recycled before its age exceedsthe number of years shown in the circle. (Safety Earth)Page 2HA030554Issue 7 Nov 12

nanodac RECORDER/CONTROLLER: USER GUIDE1 INTRODUCTIONThis document describes the installation, operation and configuration of a paperless graphic recorder/controller.The instrument comes, as standard with four input channels and is equipped, for secure archivingvia FTP transfer and/or to USB memory stick.1.1 UNPACKING THE INSTRUMENTThe instrument is despatched in a special pack, designed to give adequate protection during transit.Should the outer box show signs of damage, it should be opened immediately, and the contents examined.If there is evidence of damage, the instrument should not be operated and the local representativecontacted for instructions. After the instrument has been removed from its packing, the packing should beexamined to ensure that all accessories and documentation have been removed. The packing should thenbe stored against future transport requirements.2 INSTALLATIONCAUTIONBefore installation, ensure that the specified instrument supply voltage matches the facility supply.2.1 MECHANICAL INSTALLATIONFigure 2.1.1 gives installation details.2.1.1 Installation Procedure1. If it is not already in place, fit the IP65 sealing gasket behind the front bezel of the instrument.2. Insert the instrument through the panel cutout, from the front of the panel.3. Spring the retaining clips into place, and secure the instrument by holding it firmly in place whilst pushingboth clips towards the rear face of the panel.4. The protective membrane can now be removed from the display.Retaining spring (two places)For the sake of clarity, the panelis shown as though transparentPush springs towards panel2.1.2 DemountingFigure 2.1.1 Securing the InstrumentWARNINGBefore removing the supply voltage wiring, isolate the supply voltage and secure it against unintendedoperation.1. Isolate the mains supply and secure it against accidental operation. Remove all wiring and the USBdevice and Ethernet cable (if any).2. Remove the retaining springs by unhooking them from the sides using a small flat-blade screwdriver.3. Pull the instrument forwards out of the panel.Note: See “C1 BATTERY REPLACEMENT” on page 327 for a more detailed descriptionHA030554Issue 7 Nov 12Page 3

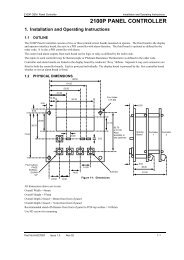

nanodac RECORDER/CONTROLLER: USER GUIDE2 Mechanical Installation (Cont.)Side ViewPanel cutout:92mm x 92mm (both -0 + 0.8mm)3.62in x 3.62in (both -0.00 + 0.03in)Minimum inter-unit spacing:Horizontal (‘x’) = 10mm (0.4in)Vertical (‘y’) = 38mm (1.5in)Top ViewFigure 2.1a Mechanical installation details (standard case)Page 4HA030554Issue 7 Nov 12

nanodac RECORDER/CONTROLLER: USER GUIDE2.1 Mechanical Installation (Cont.)Side ViewPanel cutout:92mm x 92mm (both -0 + 0.8mm)3.62in x 3.62in (both -0.00 + 0.03in)Minimum inter-unit spacing:Horizontal (‘x’) = 10mm (0.4in)Vertical (‘y’) = 38mm (1.5in)Top ViewFigure 2.1b Mechanical installation details (wash down case option)2.2 ELECTRICAL INSTALLATIONFigure 2.2 shows the locations of the various user terminations along with signal and supply wiring pinouts.2.2.1 Termination detailsThe screw terminals accept single wires in the range 0.21 to 2.08 mm 2 (24 to 14 AWG) inclusive, or two wireseach in the range 0.21 to 1.31 mm 2 (24 to 16 AWG) inclusive.Screw terminals should be tightened to a torque not exceeding 0.4Nm (3.54 lb in)HA030554Issue 7 Nov 12Page 5

nanodac RECORDER/CONTROLLER: USER GUIDE2.2 ELECTRICAL INSTALLATION (Cont.)81100 to 230Vac±15%;50/60 HzBrownBlueMains (Line) supply voltage wiringSupplyVoltageSafety EarthI/O120.4 to 28.8Vac;48 to 62 Hz or19.2 to 26.4V dc(polarity irrelevant)Low voltage option supply voltage wiringR>500R = inactiveR600R = inactiveR

nanodac RECORDER/CONTROLLER: USER GUIDE2.2.2 Low Voltage OptionThis option allows the use of a low voltage ac or dc 24 V supply. The specification in Appendix A gives fulldetails. The polarity of the dc supply connection is not important - it may be connected either way round.2.2.3 Dual Input OptionThis is a cost option, enabled on a channel-by-channel basis by means of entering the relevant password inthe ‘Feature3 Pass’ field in Instrument.Security menu described in Section 4.1.6.For each enabled channel, a pair of thermocouple, mV or mA inputs can be connected to the instrument.These inputs are called ‘primary’ and ‘secondary’, and are terminated at the analogue input terminals (AnIn1 to An In 4) as shown in ‘figure 2.2, above. The primary inputs 1 to 4 are assigned to channels 1 to 4, asnormal. Each secondary input must be soft wired to a maths channel configured as Operation = ‘Copy’ if itis to be recorded/displayed/alarmed etc.Note: Due to the nature of the input circuit, a large offset may appear for secondary thermocoupleinputs. This offset can be removed only by using the input adjust feature described in Section 4.1.9Because of this offset, the dual thermocouple input option is not suitable for AMS2750D applicationsSoft wiring is described in Section 7Maths channels are described in Section 4.5.1Channel configuration is described in Section 4.4.1Input adjust is carried out as described in Section 4.1.9SAMPLE RATEFor dual input channels, both primary and secondary sample rate is reduced to 4 Hz (250ms) from the normal8Hz (125ms).SENSOR BREAK DETECTIONInput sensor break detection is not supported for secondary inputs. The internal circuit acts as a ‘pull up’ onthe secondary input which therefore saturates high in the event of a sensor break.DUAL MILLIAMP OFFSET CORRECTIONIf ‘Dual mA’ is selected as input type, then an automatic offset correction will be made, according to the shuntvalue entered in channel configuration.INPUT RANGE LIMITATIONThere is no 10V range associated with the secondary input. Any input greater than +2V or less than -2V isdeemed to be ‘bad range’.2.2.4 Modbus Master communicationsThe master instrument can be connected directly to up to two slaves using standard ethernet network cableeither directly (single slave only) or via a hub or switch (one or two slaves). In either case, ‘straight through’or ‘crossover’ cable may be used. The cable is terminated at the RJ45 socket at the rear of the unit.2.2.5 EtherNet/IPThe Client and Server are connected in the same way as described above for Modbus Master communications,except that there can be only one client and one server.HA030554Issue 7 Nov 12Page 7

nanodac RECORDER/CONTROLLER: USER GUIDE3 OPERATIONOn power up a default or customsplash screen appears and remains visible whilst the unit is initialising.If during this process a network broadcast storm is detected, the unit stops, displaying anetwork failure icon until the broadcast storm has cleared, after which the initialisation processresumes.3.1 INTRODUCTIONThe operator interface consists of a display screen and four push buttons.3.1.1 Display ScreenThe display screen is used both to display channel information (in one of a number of display modes), andto display the various configuration screens which allow the user to setup the recorder to display the requiredchannels, to set up alarms and so on. Display modes are described in Section 3.4 below; configurationis described in Section 4.In display mode, the screen is split horizontally into three areas (figure 3.1.1)1. a faceplate giving channel details.2. the main display screen showing channel traces etc.3. the status area, displaying instrument name, the current time and date and any system icons.FaceplateChannel 1 6.23VMain display screenStatus areaInstrument name12:01:08Figure 3.1.1 Display mode screen (vertical trend)In configuration mode, the entire display screen is devoted to the selected configuration menu.3.1.2 Navigation PushbuttonsHomeConfigurationGo to ViewHistoryFaceplate cycling (On)Operator NotesDemand ArchivingLog outFigure 3.1.2 Top level menu (Engineer level access)There are four navigation buttons, called ‘Page’, ‘Scroll’, ‘Lower’ and ‘Raise’ located below the screen. Thegeneral properties of these buttons are described in the remainder of this section, but some have additional,context sensitive functions, which, for the sake of clarity are not described here but in the relevant sections(e.g. ‘Message summary’) of the manual.Page 8HA030554Issue 7 Nov 12

nanodac RECORDER/CONTROLLER: USER GUIDE3.1.2 Navigation Pushbuttons (Cont.)PAGE BUTTONFrom any non-configuration page, pressing this push button causes the top level menu (figure 3.1.2) to appear.The figure shows the menu for a user logged in with ‘Engineer’ level access. Other access levels mayhave fewer menu items.Within configuration pages, the Scroll button can be used as an enter key to select lower menu levels. In suchcases the page button is used to reverse this action, moving the user up one menu level per operation.SCROLL BUTTONFrom trending pages, operation of the scroll push-button scrolls through the channels enabled in the group.The Faceplate cycling ‘Off’ selection can be used to keep a particular channel permanently displayed, andthe scroll pushbuttons can then be used to select channels manually.In configuration pages, the scroll key operates as an ‘enter’ key to enter the next menu level associated withthe highlighted item. Once the lowest menu level is reached, operation of the scroll key allows the value ofthe selected item to be edited by the relevant means (for example, the raise/lower keys, or a keyboard entry).The ‘Page’ key is used to move the user back up the menu structure, until the top level menu is reached,when the scroll key can be used again to return to the Home page.The scroll button is also used to initiate user wiring as described in Section 7.RAISE/LOWER BUTTONSWithin trending displays, the Raise and Lower keys can be used to scroll through the enabled display modesin the sequence: vertical trend, horizontal trend, vertical bargraph, horizontal bargraph, numeric, verticaltrend... and so on.Within configuration pages, these pushbuttons act as cursor keys, allowing, for example, the user to highlightmenu items for selection using the scroll button, and in many cases allowing the user to select one froma number of alternative values within menu items. These keys are also used to navigate through the virtualkeyboards (Section 3.6) and number pads used to enter text or numeric strings.3.1.3 On Screen HelpThe top level configuration menu includes contextual help text on the right-hand half of the screen. Mostlythis text fits within on screen height. Where this is not the case, the text can be moved up or down the screenby holding the Page button operated whilst using the up and down arrows to move the text.The down arrow moves the text upwards on the screen; the up arrow moves it downwards.Select configuration menuLogic (2 Input)Logic (8 input)MultiplexerMath (2 input)Timer<strong>User</strong> valuesAlarm SummaryThe timer functionblock offers a universaltimer which may bere-configured betweensingle pulse outputsand re-triggeringoutputs. Timer typesare:On pulse on-timer.On-screen help.(Use the Page button with thedown arrow to access hiddentext at the bottom of the screen)+Figure 3.1.3 On-screen help (typical)HA030554Issue 7 Nov 12Page 9

nanodac RECORDER/CONTROLLER: USER GUIDE3.2 PROCESS VARIABLE DISPLAYAs discussed above, the operator interface consists of a display screen and associated push buttons. Thedisplay screen shows process variables in one of a number of formats, or operational details (notes or alarmhistory for example), or configuration details for use in setting up the recorder to produce the required displaysand history formats. The remainder of section three discusses the process variable displays, alarm displaysand so on; configuration details are to be found in Section 4.Note: Some of the items below can be selected for use only by users with a suitable permission levelas set up in the ‘Instrument’ ‘Security’ menu described in Section 4.1.6.Figure 3.2 below, depicts a typical trend display and gives details of the various areas of the display page.Current point nameCurrent point ‘pen’Channel 1 6.23VCurrent point value and unitsCurrent point scaleTime/date stampsInstrument nameRecording statusInst name12:01:08Figure 3.2 Typical display screen (Vertical trend)Current time/dateFigure 3.2 shows a vertical trend page. Operating the Raise/Lower push-buttons allows the user to scrollthrough the other display modes: Horizontal trend, Vertical bargraph, horizontal bargraph, numeric, verticaltrend... and so on. All these display modes are described in Section 3.4, below.A display mode can also be selected from the Top level menu ‘Go To View’ item which appears when the‘Page’ key is operated.The scroll button can be used to scroll through the points in the group, overriding the ‘Faceplate Cycling’on or off selection3.2.1 Alarm IconsNotes:1. A full discussion of alarms is given in the Channel Configuration section of this manual (Section4.4.3)2. Trigger alarms do not display threshold marks or bars, or faceplate symbolsThe alarm icons shown below appear in some display modes. The icons on a channel faceplate show thestatus of that channel’s alarm(s), as follows:Icon is flashingalarm is active but unacknowledged or it is an Auto alarm which is no longer activebut which has not been acknowledgedIcon steadily illuminated the alarm is active and has been acknowledged.Alarm thresholds and deviation alarm bars appear for horizontal and vertical trend modes. For deviationbars, the bar stretches from (Reference - Deviation) to (Reference + Deviation). Vertical and Horizontal bargraphmodes display only absolute alarm symbols.Page 10HA030554Issue 7 Nov 12

nanodac RECORDER/CONTROLLER: USER GUIDE3.2.1 Alarm Icons (Cont.)Absolute HighAbsolute LowDeviation HighDeviation LowDeviation BandRising Rate of changeFalling Rate of changeDigital HighDigital LowTable 3.2.1 Alarm icons3.2.2 Status Bar IconsThe following items can appear in a dedicated window immediately to the left of the time and date, at thebottom right-hand corner of the display. The width of this window expands as the number of icons increases,and the instrument name is truncated, as necessary, to make room.SYSTEM ALARMSThis indicator appears, flashing, if any one or more of the alarms listed below is active. The System Alarmssummary page (accessed from ‘Go to View in the top level menu) allows the user to view such system alarmsas are active. It is not possible to ‘acknowledge’ system alarmsArchive DisabledArchiving FailedArchiving TimeoutBattery failureBroadcast Storm detectedClock failureChannel errorDatabase failureDHCP Server failureFTP Archiving file lostFTP Archiving to slowAn unattended archiving strategy has temporarily been disabled.An unattended archiving strategy has failed to complete.A configured archiving strategy has timed out.Indicates that the battery is approaching the end of its useful life, orthat it is missing or is completely exhausted. Immediate battery replacementis recommended (Appendix C; section C1).Networking is limited until the storm has passed.The internal clock was found to be corrupt at power up, or that thetime has never been set. Time is forced to 00:00 1/1/1900. Can becaused by battery failure, in which case a battery failure message appears.The error is cleared by setting the time and date.Indicates a hardware failure in the channel circuit or in the internalcold junction temperature measurement.Corrupted EEPROM or flash memory.For units with ‘IP Type’ set to ‘DHCP’ (Network.Interface configuration)this alarm occurs if the instrument is unable to obtain an IP addressfrom the server.A file has been deleted that had not yet been archived. Possible causes:Communications with the server could not be established,; archiveis disabled; archive rate too slow.The archive rate is too slow to prevent the internal memory from overflowing.The recorder effectively switches to ‘Automatic’ (Section4.2.2) to ensure that data is not lost.(Continued)HA030554Issue 7 Nov 12Page 11

nanodac RECORDER/CONTROLLER: USER GUIDE3.2.2 Status Bar Icons (Cont.)FTP Primary Server FailureFTP Secondary Server FailureMaths channel failureMedia archiving file lostMedia archiving to slowMedia fullMedia missingNon-volatile memory failureNon-volatile Write Frequency warningRecording failure (message)USB overcurrentWiring failureThis error occurs if the recorder fails to establish connection with theprimary server, after two attempts. After the second attempt fails, therecorder attempts to establish connection with the secondary serverinstead. Primary and secondary server details are entered in the Network.Archiving area of configuration (Section 4.2.2).This error occurs if the recorder fails to establish connection with thesecondary server, after two attempts. Primary and secondary serverdetails are entered in the Network.Archiving area of configuration(Section 4.2.2).Appears if, for example, the divisor of a divide function is zero.A file has been deleted that had not yet been archived. Possible causes:Memory stick missing, full or write protected; archiving has beendisabled; archiving rate too slow.The archive rate is too slow to prevent the internal memory from overflowing.The recorder effectively switches to ‘Automatic’ (Section4.2.2) to ensure that data is not lost.Archive storage device is full. The alarm becomes active only whenan archive is in progress.No archive storage device present when archive attempted.RAM copy of non-volatile parameters is corrupted.One or more parameters are being written frequently to non-volatilememory. If this continues, it may lead to ‘memory depletion’ (i.e. thememory will no longer be able to store values correctly). A commoncause of this problem is frequent writes over Modbus comms.Message explains reason for failure.USB power fault - too much current (i.e. >100mA) is being drawn by aUSB device.The user wiring has failed to verify, i.e. one or more wires has beendetected that does not have both a source and a destination defined.This may be the result, for example, of power loss during a downloadfrom iTools.CHANNEL ALARMThis indicator appears if any channel (including channels not in the display group) is in an alarm state. Thesymbol is illuminated continuously if all alarms are acknowledged or flashes if any one or more alarms is unacknowledged.Alarms are acknowledged from the Root menu ‘Alarm summary’ item as described in Section3.3.3 or in the Channel configuration area (Section 4.4.3) if the user’s access permission is appropriate.USBThis icon appears whenever a memory stick (max. capacity 8GB) or other supported USB device (Section 8)is plugged into the USB port at the rear of the recorder.When data transfer is in progress between the instrument and the memory stick, the icon changes to a ‘busy’version.CAUTIONThe Memory stick must not be removed while archiving (demand or automatic) is inprogress, as to do so may irreparably damage the file system of the memory stick,rendering it unusable. It is recommended that all archiving be suspended before thememory stick is removed.Memorystick fittedTransfer inprogressFTP ICONThe FTP icon appears whenever transfer activity is taking place.Page 12HA030554Issue 7 Nov 12

nanodac RECORDER/CONTROLLER: USER GUIDE3.2.2 Status Bar Icons (Cont.)RECORD ICONOne of four icons appears at the bottom left corner of the display to indicate recording status.RecordThis indicates that the recorder is recording the items selected in the Group Recording area of configuration(Section 4.3).StoppedThis means that ‘Enable’ has been set to ‘no’ in the Group Recording area of configuration (Section 4.3).Trending is not affected.Paused (Suspended)This means that recording has been paused by a wire to the Suspend parameter (Group Recording area ofconfiguration (Section 4.3) going true (high). Trending is not affected.In ConfigurationThe recorder has been placed in configuration mode either at the user interface, or via iTools. Recording isstopped until the recorder is no longer in configuration mode. For each non-recording state (Stopped,Paused or In Configuration). A new history file is created when the unit comes out of configuration mode.Note: For recording to be enabled, configuration status must be ‘logged out’ both at the instrumentand at iTools.MESSAGE ICONThis ‘envelope’ icon appears when a message is generated and it remains on display until the Message Summaryis accessed, when it is removed from the display until the next new message is generated.AUTOTUNE ICONFor instruments fitted with the Loop option, this symbol appears during the Autotune process.3.2.3 Breaks in recordingBreaks in recording can be caused by the unit being powered down, by the user entering configurationmode or when the recorder time is changed manually. In vertical and horizontal trend modes, a line is drawnacross the width/height of the chart to indicate that recording has been interrupted.On power up, a red line is drawn across the chart. In ‘History’, if messages are enabled the message:Date Time System power upis printed on the chart, together with the configuration and security revisions.On exiting configuration mode, a blue line is drawn on the chart and in ‘History’, if messages are enabled,the messages:Date Time Logged out.Date Time Config Revision: N was N-1 (assuming a configuration change was made)Date Time Logged in as: Engineerappear on the chart.When the instrument time is changed (manually - not through daylight saving action) a green line is drawnon the chart and in ‘History’, if messages are enabled, the message:Date Time Time/Date changedappears on the chart.HA030554Issue 7 Nov 12Page 13

nanodac RECORDER/CONTROLLER: USER GUIDE3.3 TOP LEVEL MENUThis menu appears when the page key is operated from any non-configuration page. The menu items displayeddepend on the access permission of the user. One of the menu items is highlighted, and if the scrollkey is operated, then it is the highlighted item that is ‘entered’.Figure 3.3 shows the top level menu for Engineer level access.Section 3.3.1Section 3.3.2Section 3.3.3Section 3.3.4Section 3.3.5Section 3.3.6Section 3.3.7Section 3.3.8HomeConfigurationGo to ViewHistoryFaceplate cycling (On)Operator NotesDemand ArchivingLog outPage keyScroll keyFigure 3.3 Top level menu3.3.1 HomeOperating the scroll key whilst ‘Home’ is highlighted causes a return to the ‘Home’ page. By default, this isthe vertical trend mode, but the mode can be changed in ‘Instrument. Display’ configuration (Section 4.1.3)3.3.2 ConfigurationOperating the down arrow key highlights the ‘Configuration’ item. Operating the Scroll key enters the configurationsubmenu described in Section 4of this manual.Note: ‘Configuration’ appears only if the user has an appropriate access level.Page 14HA030554Issue 7 Nov 12

nanodac RECORDER/CONTROLLER: USER GUIDE3.3.3 Go to ViewOperating the scroll key whilst the ‘Go to view’ item is highlighted, calls the Go to view submenu (figure3.3.3a). This allows the user to view channel alarms, system alarms, messages or to select a different displaymode.Alarm SummarySystem AlarmsMessage SummaryVertical TrendHorizontal TrendVertical BargraphHorizontal BargraphNumericAlarm PanelControlDual LoopCascadeProgrammerSteriliserPromote ListModbus MasterEtherNet/IPAlarm SummarySystem AlarmsMessage SummaryVertical TrendHorizontal TrendVertical BargraphHorizontal BargraphNumericAlarm PanelControlControl (Dual Loop)CascdeProgrammerSteriliserPromote ListModbus MasterEtherNet/IPFigure 3.3.3a Go to view submenuNotes:1. If an option (e.g. ‘Steriliser’) is not fitted, its display mode does not appear in the list.2. Some display modes must be enabled in Instrument. View configuration (Section 4.1.3) beforethey become available.HA030554Issue 7 Nov 12Page 15

nanodac RECORDER/CONTROLLER: USER GUIDE3.3.3 Go To View (Cont.)ALARM SUMMARYFor each active alarm, this page displays the channel identifier with alarm number (e.g. C1(2) = channel 1;alarm 2), the channel descriptor, the alarm threshold the current process value and an alarm type symbol.To return to the top level menu, operate the Page key.Notes:1. The background colour to the channel ID is the same as that chosen for the channel.2. A prefix ‘C’ in the channel ID means that this is a measuring channel; A prefix ‘V’ means that thisis a virtual channel (i.e. a totaliser, counter or maths channel)Channel ID(Alarm number)Channel descriptorAlarm SummaryC1(2) Furnace 1 temp 1 750.00 798.39C2(1) Furnace 1 temp 3 750.00 763.89C3(1) Furnace 1 temp 2 590.00 603.39C4(1) Furnace 2 temp 1 645.00 630.71Alarm ThresholdChannel current process valueAlarm Type indicatorPage keyScroll keyFigure 3.3.3b Alarm summary page with acknowledge confirmation displayALARM ACKNOWLEDGEMENTTo acknowledge an alarm from this view:1. Use the up and down arrows to highlight the requiredalarmC1(2)C2(1)C3(1)C4(1)Alarm SummaryFurnace 1 temp 1 750.00 763.26Furnace 1 temp 3 750.00 770.01Furnace 1 temp 2 590.00 595.83Furnace 2 temp 1 645.00 644.332. Operate the scroll button. The ‘Acknowledge alarm’window appears.Acknowledge alarm?No C2(1) All3. Use the up arrow to highlight the relevant field (C2(1) in thisexample), or ‘All’ if all alarms are to be acknowledged.Acknowledge alarm?No C2(1) All4. Operate the scroll key to confirm. If the alarm fails to respond,this may be due to the fact that it has been configured as a ‘Manual’ alarm, and the trigger has not yetreturned to a ‘safe’ (non-alarm) state, or it could be that the instrument is in a logged out state.SYSTEM ALARMSOperating the scroll button whilst the ‘System Alarms’ field is highlighted displays a list of all currently activesystem alarms. Section 3.2.2 contains a list of system alarms and their interpretations. To return to the toplevel menu, operate the Page key.A further operation of the scroll button displays a ‘Help Information’ page, giving the reason for the highlightedalarm.Operate the scroll button again to return to the system alarm display.Page 16HA030554Issue 7 Nov 12