Red Sandalwood

A Guide to Red Sandalwood

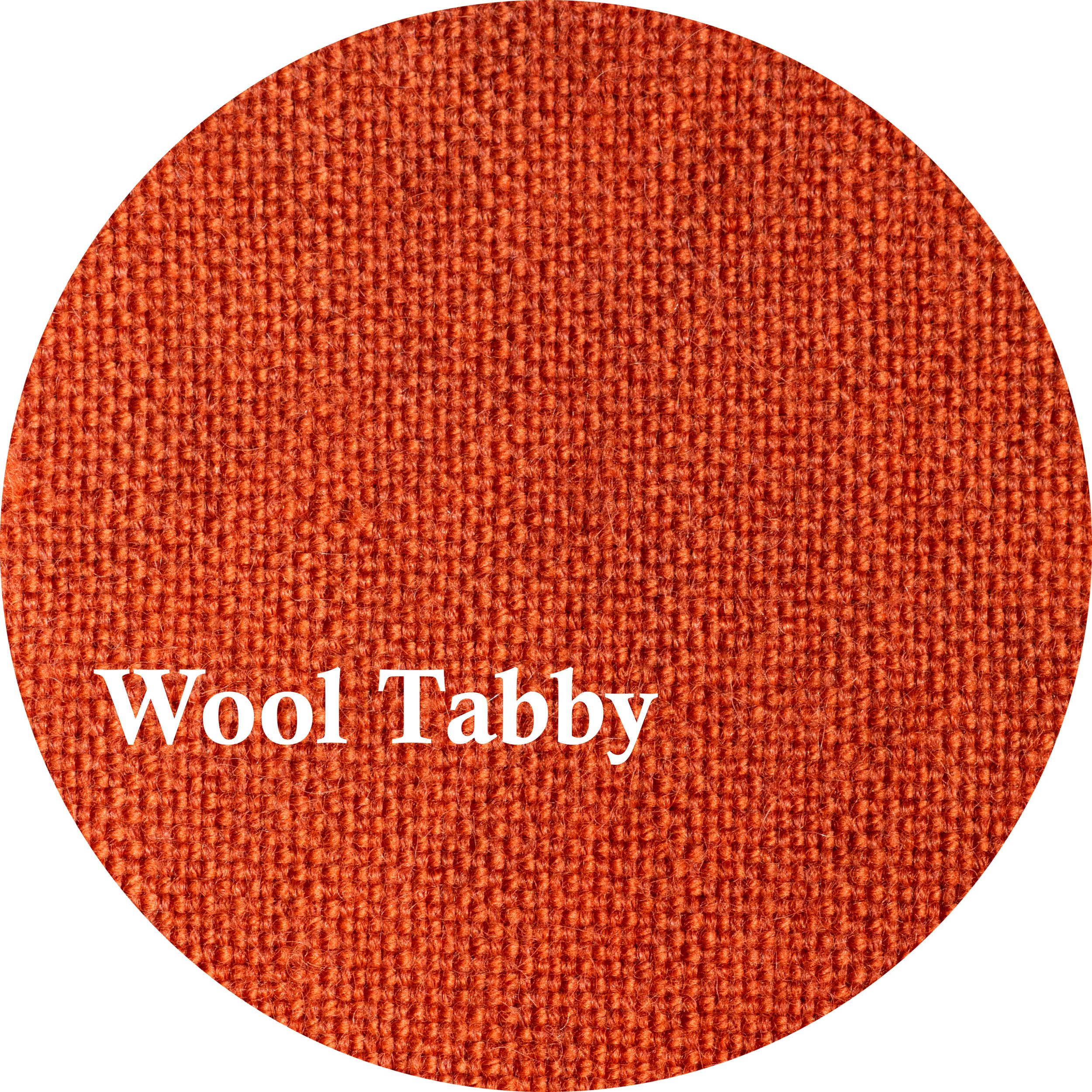

Shepherd Textiles Red Sandalwood contains the finely ground heartwood of the true Red Sandalwood tree, pterocarpus santalinus. Red Sandalwood contains a pigment called santalin that dyes shades of brick red on natural fibers. Santalin is mostly insoluble in water, so different extraction techniques are required. You will need either grain spirits (e.g., cheap vodka) or soda ash and cream of tartar to get the best colors. Red Sandalwood has a good affinity for all protein fibers, and gives lighter strawberry shades on cotton. Our Red Sandalwood comes from non-endangered forestries in Andhra Pradesh. Use at 30% weight-of-fabric for a pleasant terracotta red, or 100% weight-of-fabric for a deeply saturated brick red. For more detailed background research and notes on our experiments, visit our page Experiments with Red Sandalwood Dye.

1. Background on Red Sandalwood

There are a number of species of hardwood that are occasionally referred to as red sandalwood, including African Padauk (pterocarpus soyauxxi) and Camwood (baphia nitida). However, the true Red Sandalwood is pterocarpus santalinus, a small tree native to southeastern India. Historically known as red sanders, saunders wood, or santal wood, pterocarpus santalinus contains a strong red pigment called santalin in its heartwood. Santalin gives a brick-red dye on natural fibers, and during the Victorian era it was used by dyeing houses in Europe as an alternative to madder red. Today it is still used on a smaller scale to color pharmaceutical and cosmetic products—an alcohol tincture of Red Sandalwood will instantly dye anything it touches bright red.

Red Sandalwood is one of those complex dyestuffs that contains multiple pigments. There at least 5 in total, including the red santalin and various orange, violet, and brown pigments. To get a clear red out of Sandalwood the santalin has to be extracted from the wood and then applied at high heat. Unfortunately, santalin is mostly insoluble in water—indeed, the Victorians referred to it as one of the “insoluble reds.” Even in boiling water only about 10% of the available santalin will be extracted from the wood. Sandalwood can be simmered in a water dye bath like other natural dyes, but doing so is extremely inefficient. However, santalin is extremely soluble in ethanol, and soaking the wood powder in grain spirits will liberate up to 90% of the santalin; the difference in the dyebath is dramatic. We provide instructions for two ways of extracting the red, one using alcohol and one using an alkaline modifier, but the alcohol extraction is superior by far.

Red Sandalwood has an evocative name, a wonderful incense-like smell, and gives a beautiful brick red on correctly prepared fibers. The reason it is not more commonly used as a natural dye is that for most of the 20th century it was considered endangered and export of the heartwood was strictly controlled by the Indian government. Pterocarpus santalinus grows mostly in a single state—Andhra Pradesh—and it is highly vulnerable to forest fires and illegal logging for furniture and trinkets. In the 1950s the Indian government banned commercial harvesting of the species, and in 1994 it was designated “endangered” by the IUCN. However, the Indian government’s conservation measures have been successful, and in 2018 pterocarpus santalinus was removed from the endangered species list. Our Red Sandalwood comes from sanctioned forestry programs in Andhra Pradesh, and gives natural dyers an opportunity to experiment with a dye that has gone largely unused since the early 20th century.

One of the Forgotten Natural Colors

2. Safety Precautions

DO NOT INGEST. This product is intended for textile dyeing, not as an herbal supplement.

Avoid eye contact. If eye contact occurs, rinse with cool water.

Not for use as a cosmetic additive; do not apply directly to skin or hair.

Open carefully to avoid spilling or creating dust. Work in a well-ventilated space, and avoid inhaling sawdust. Wear a mask if necessary while working with fine powders.

If a spill occurs, quickly wipe up with a paper towel or disposable rag.

Use only dye pots and utensils dedicated to dyeing. Do not use any pots, containers, spoons, tongs, thermometers, or other utensils that will be used for food preparation.

Red Sandalwood will stain stainless steel dye pots and utensils. If using a metal dye pot, you will probably need to scrub it with a scouring pad to clean it out when you are finished.

Red Sandalwood powder, and all dye baths and mordant liquors made while dyeing, should be kept out of reach of children and pets. Use only with adult supervision.

Prop 65 Warning: The product contains wood dust, which is known to the State of California to cause cancer.

Shepherd Textiles, LLC is not liable for any misuse of this product or any unintended staining of your clothing, workspace, or other property. Use only as directed.

3. Recommended Supplies

Dye pot. Use a dye pot large enough to hold all your fibers, with plenty of room for them to move around and for the liquid to circulate freely.

Metal tongs. A pair of tongs is useful for stirring and taking fabric out. Use tongs dedicated to dyeing, and not for food preparation.

Rubber gloves. Wear rubber gloves while handling mordanted/dyed fiber before it has been rinsed.

Candy thermometer. The best way to keep track of temperature is to use a candy thermometer that clips to the side of the dye pot.

Scale. Use a scale to weigh out fiber, mordant, and dyestuff.

Alum mordant. The alum usually used for mordanting is aluminum potassium sulfate, also known as potash alum. It is the same alum that you can find in a jar in the spice section at the grocery store.

Cheap vodka & a mason jar. For making a sandalwood tincture.

Fine mesh strainer. For straining out the wood after extraction.

4. Preparation: Mordanting with Alum or Tin (Optional)

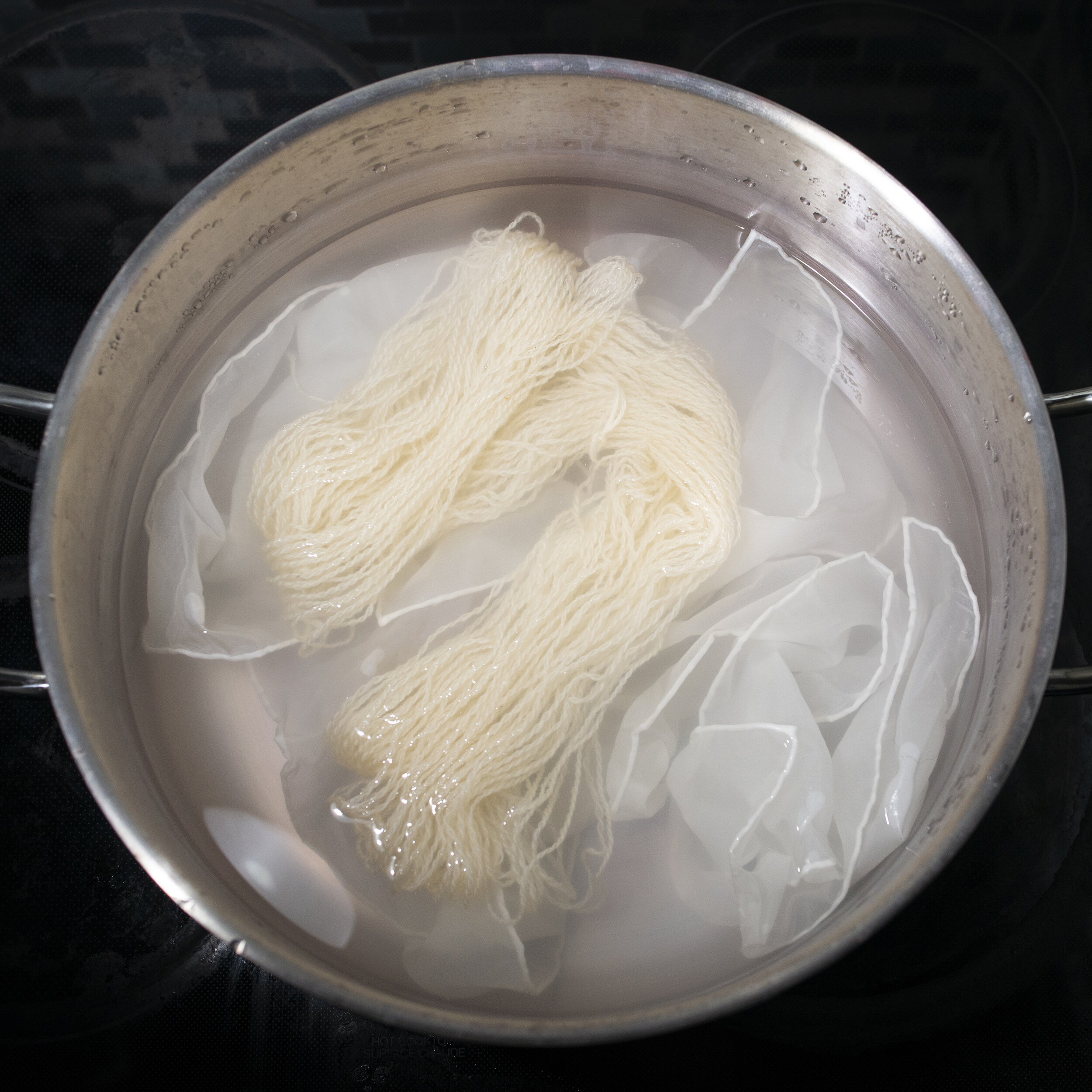

Red Sandalwood is substantive on wool and silk: it dyes permanently without the need for any mordant. However, mordants will increase the color depth and fastness. An alum mordant may shift the color a bit toward orange, while tin usually keeps it closer to brick. If possible, soak your fibers in water for a few hours before mordanting, so that the mordant will penetrate deeply and evenly. Make sure to weigh the fibers first, while they are still dry.

For protein fibers (wool, silk, alpaca, etc.): Mordant at 12% WOF with alum or 2% WOF with tin*.

Weigh out the fibers you plan to dye (while they are dry). Multiply that weight by 0.12 to get the amount of alum you will need. If mordanting with tin, use 2% WOF of tin powder plus 5% WOF of cream of tartar (multiply the weight of the fibers by 0.02 to get the correct amount of tin and 0.05 to get the correct amount of cream of tartar).

Fill your dye pot with hot tap water, leaving enough room for the fiber.

Weigh out the correct amount of mordant powder (and cream of tartar, if using tin) and pour it into the dye pot. Mix with a spoon or metal tongs until it has dissolved.

Gently place your fibers into the mordanting solution.

Heat mordant bath to 180F and maintain heat for 1 hour. If you don’t have a candy thermometer, you will have to estimate the temperature. At 180F, steam vapor will be rising off the water but it will not be bubbling. If your mordant bath starts to bubble, turn down the heat.

Stir every 15 or 20 minutes to make sure fibers mordant evenly. If they do not, the dye will take better in some places than others.

After an hour, remove from heat and let cool to room temperature. Once cool, you can immediately proceed to rinsing, or you can leave the fibers to steep overnight in the mordant bath. This can dramatically improve results, especially when dyeing thick or tightly woven fabrics.

When ready to rinse, put on rubber gloves and gently squeeze excess mordant solution back into the pot. Rinse fibers briefly in lukewarm water. The fiber does not need to be thoroughly washed, but any excess mordant should be rinsed out. Set aside until ready to dye. Keep out of reach of children and pets.

Dispose of mordant solution according to local guidelines.

For cellulose fibers (cotton, linen, etc.): Treat with a tannin before mordanting.

Scour (clean) the cotton by adding 1 tsp of soda ash and 1 drop of dish soap to a 5-gallon dye pot. Add the cotton and heat to 180F-190F for an hour, stirring occasionally. Remove from heat, and when cool enough to handle, rinse and wring out well.

Apply Sumac Extract to the cotton to tan it. Fill your dye pot with just enough hot water for your fibers to move around freely - the more concentrated the tannin bath, the stronger the results will be. Dissolve 20% WOF Sumac Extract into the water. Add the cotton, raise the heat to 180-190F, and maintain for an hour. Remove from heat and allow to slowly cool to room temperature: for best results, steep overnight. After steeping, remove the cotton and gently squeeze out excess liquid (wearing rubber gloves), but do not rinse, as this may rinse out the tannins before they can bond to the mordant. For the very strongest results, hang the cotton up and let it dry before proceeding to mordanting.

Prepare an alum mordant bath using either (a) 20% weight-of-fabric alum + 5% soda ash (washing soda), or (b) 20% weight-of-fabric of aluminum lactate. Either option will create a relatively neutral pH mordant bath that bonds well with cotton.

Heat the mordant bath to 150°F or 160°F, place the cotton in it, and raise the heat to 190°F. Maintain for one hour, stirring occcasionally to make sure the fibers mordant evenly. After one hour, remove from heat. When cool enough to handle safely, remove fibers and rinse well in lukewarm water.

*Tin mordant (stannous chloride powder) is caustic and can cause eye and skin burns. Please read your vendor’s Safety Data Sheet (SDS) before using and observe all recommended precautions. Wear gloves and eye protection when handling tin powder and tin mordant baths.

5. Preparation: Making a Sandalwood Tincture

There are several ways of extracting the dyestuffs from Red Sandalwood, but the most effective by far is soaking it in alcohol. This will extract up to 90% of the available santalin, whereas boiling water will extract about 10%. The difference in the dyebath is dramatic. Making a Red Sandalwood tincture is very easy, and it can be kept in a jar and used as a base for making a red dye bath whenever it is convenient. However, the extraction requires flammable alcohol, so exercise caution and keep it away from open flame.

Add Red Sandalwood powder to a clean glass mason jar large enough to hold the powder and a few cups of liquid. For deeply saturated colors, use 100% weight-of-fabric (WOF) of Red Sandalwood powder. Of course you can always add more than you plan to use immediately—the tincture will hold almost indefinitely.

Add between 2/3 cup and 1 cup of grain spirits for each ounce of Red Sandalwood powder—you want there to be enough liquid on top so that it will be easy to decant. We use bottom shelf, 100-proof vodka, but any clear spirit should do.

Mix well. Use a disposable plastic spoon or a metal spoon that can be scrubbed clean. Whatever you put in the solution from now on will be dyed red. The spirits should quickly turn a dark garnet red color.

Seal the jar and place somewhere out of reach of children and pets. You may wish to label it so nobody mistakes it for something edible.

Stir once or twice over the next few hours, then leave to steep at least overnight.

Congratulations! You have just made one of the strongest red stains known to nature. If you would like to test it, try dipping a small swatch of fabric directly into the tincture—it should immediately dye red. Store the tincture carefully and out of reach of children. When it comes time to build the dyebath, add only the liquid and not the extracted wood powder. The wood will settle to the bottom of the jar, so if you lift it gently you should be able to easily decant the tincture without pouring out any of the wood. After decanting, you can also add more spirits to get more of the santalin out of the wood powder.

CAUTION: Alcohol is flammable. Store away from heat and open flame. Do not add to dyebath while the flame is on! Add to the water first, seal the jar, then gently apply heat to the dye pot. Turn on ventilation fan if available; keep dye pot covered to prevent fumes from seeping out.

The Recipes

5. Recipe: Brick Red

The santalin in Red Sandalwood naturally dyes fibers a brick red color. By using alcohol to extract the dyestuff, and using 100% weight-of-fabric (WOF), a rich and deeply saturated red can be achieved. Santalin is substantive to protein fibers like wool and silk and gives good results even without a mordant. However, a mordant will noticeably deepen the color. Alum may shift the color a bit toward orange, while tin tends to keep it closer to brick red, but both work well. Red Sandalwood can also give good reds on cotton, although the cotton will need to be thoroughly tanned and mordanted first. Use a smaller concentration of tincture to get pleasant terracotta and peach colors.

Follow the directions in Section 5 to make an alcoholic tincture of Red Sandalwood. Use 100% weight-of-fabric (whatever the dry weight of the fibers is, use the same weight of Red Sandalwood in the tincture).

Fill your dye pot mostly full with warm water. Decant the Red Sandalwood tincture from the mason jar into the dyebath—the dark garnet tincture will turn a bright cloudy orange as soon as it hits the water. Pour slowly and carefully so as not to get any of the wood powder in the dyebath, otherwise it will get stuck in your fiber and be very difficult to get out.

Add your pre-mordanted (optional), pre-soaked fibers to the dye bath.

Observe safety precautions when heating alcohol: open windows for ventilation, turn on range fan, and keep pot covered to prevent vapors from being inhaled or igniting.

Slowly raise the temperature to 185F-190F. Maintain for two hours, stirring occasionally to make sure the fibers dye evenly. Remove from heat and allow to cool to room temperature.

When cool, remove the fibers and rinse briefly in lukewarm water. You can either proceed immediately to rinsing with detergent, or hang the fabric up to dry first to help the color set. Make sure to hang it up in the shade somewhere where dripping dye will cause no damage. Direct sunlight may fade the color before it has had time set.

For final rinsing, we recommend using a PH-neutral detergent like Synthrapol that is designed to wash out loose dye. Follow the manufacturer’s directions for best results. CAUTION: Red Sandalwood will bleed if not thoroughly rinsed out after dyeing.

Hang up to dry out of direct sunlight.

6. Recipe: Terracotta

Lighter shades like terracotta can be achieved by using the recipe for Brick Red and simply adding less of the tincture to the dyebath. However, there is another way of extracting santalin from Red Sandalwood if you prefer not to use alcohol. Santalin is moderately soluble in an alkaline bath, so simmering the wood powder with washing soda (soda ash) will get enough color out to dye fiber a pleasant terracotta red. However, the dye bath will have to be returned to a slightly acidic state before the fiber is added.

Fill your dye pot with hot water. Adjust the PH to 10 using soda ash (also known as washing soda). About one teaspoon per five gallons of water is usually sufficient; confirm with PH strips.

Weigh out 30% weight-of-fabric (WOF) of Red Sandalwood powder. Sprinkle the wood powder into the dyebath and stir well.

Heat the dyebath to 180F. The water should take on a dark maroon or violet color, sometimes with a greenish cast. This is sign the extraction is successful—santalin turns violet in an alkaline solution.

Maintain heat at 180F for an hour, then cover and allow to cool to room temperature. For best results, steep overnight.

When cool, strain the dyebath through cheesecloth, an old t-shirt, or a very fine mesh strainer. Any wood left in the final dyebath can cause splotches on your fiber, and the tiny bits of wood will be impossible to pick out of yarn. HINT: If you let it steep overnight, the wood powder should settle to the bottom of the cooled extraction bath. If you avoid shaking or disturbing the dye pot, you should be able to gently pour off most of the violet liquid while leaving all the wood at the bottom.

Dispose of the wood powder, rinse out your dye pot, and return the violet extraction liquid to it.

Adjust the PH to 5 (slightly acidic) using Cream of Tartar. About three teaspoons per five gallons of water should be enough; confirm with PH strips. You may need to stir vigorously to dissolve the Cream of Tartar; heat the dyebath up a little of necessary.

When the PH has been properly adjusted, the violet liquid will turn a deep red or red-orange color. The dyebath is now ready for dyeing.

Add pre-mordanted (optional), pre-soaked fibers to the dyebath.

Heat to 185-190F for 2 hours, stirring occasionally to make sure the fibers dye evenly. Remove from heat and allow to cool to room temperature.

When cool, remove the fibers and rinse briefly in lukewarm water. You can either proceed immediately to rinsing with detergent, or hang the fabric up to dry first to help the color set. Make sure to hang it up in the shade somewhere where dripping dye will cause no damage. Direct sunlight may fade the color before it has had time set.

For final rinsing, we recommend using a PH-neutral detergent like Synthrapol, it is designed to wash out loose dye. Follow the manufacturer’s directions for best results. CAUTION: Red Sandalwood will bleed if not thoroughly rinsed out after dyeing.

Hang up to dry out of direct sunlight.

7. Recipe: Texas Orange

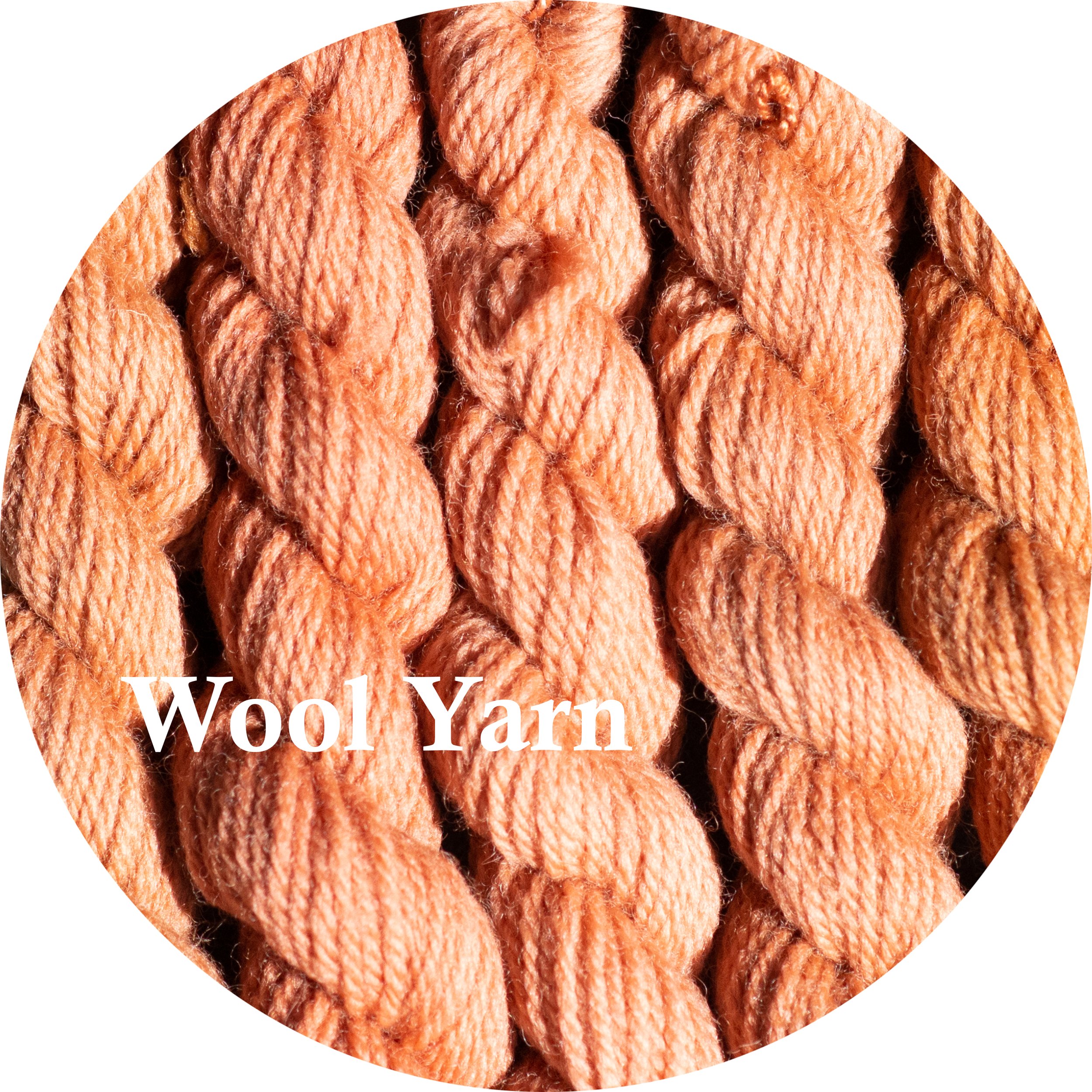

This is an oddity we discovered while experimenting with different extraction techniques. Red Sandalwood contains at least five pigments; although red santalin is the dominant dyestuff, there are also orange, yellow, and violet dyes. Dyeing alum-mordanted wool slowly and at a low temperature will draw in more of the orange and less of the red, yielding a deeply saturated burnt orange color.

Follow the steps for doing an alkaline extraction in the recipe for “Terracotta” (see Section 6). However, in Step 2, use 100% weight-of-fabric of Red Sandalwood.

When you get to Step 9 (adding fiber), add wool that has been thoroughly mordanted with alum. For best results, use wool that has steeped in an alum mordant bath at least overnight. This recipe also works on alum-mordanted silk, but the results are less dramatic.

Rather than heat the dye bath to 185F, keep it at 140F for three hours. The lower temperature will change the way the dye applies to the wool.

After three hours, remove from heat and let cool to room temperature.

Remove the fibers and rinse briefly in lukewarm water. You can either proceed immediately to rinsing with detergent, or hang the fabric up to dry first to help the color set. Make sure to hang it up in the shade somewhere where dripping dye will cause no damage. Direct sunlight may fade the color before it has had time set.

For final rinsing, we recommend using a PH-neutral detergent like Synthrapol that is designed to wash out loose dye. Follow the manufacturer’s directions for best results. CAUTION: Red Sandalwood will bleed if not thoroughly rinsed out after dyeing.

Hang up to dry.

8. More Information

For more information about dyeing with Red Sandalwood, including detailed research and notes on some of our experiments, please visit our page Experiments with Red Sandalwood Dye.

All images and text are copyright of Shepherd Textiles, LLC. Do not reproduce without written permission and attribution.