Understanding the Importance of Subwoofer Box Internal Bracing

Box bracing is a fundamental yet frequently underestimated aspect of subwoofer box design, especially among audio enthusiasts. This crucial process involves strategically adding internal braces to the walls of the enclosure. The primary objective of these braces is to enhance the rigidity of the box, which plays a vital role in reducing unwanted vibrations that can adversely affect sound quality.

The impact of proper box bracing on a subwoofer’s performance cannot be overstated. It contributes significantly to the sound quality by ensuring the audio output remains crisp and clear. When the enclosure walls are sufficiently reinforced with braces, they become less prone to vibrational interference, leading to a cleaner and more precise bass response. This improvement in bass response is not just about increasing the volume; it’s about enriching the depth and texture of the bass, allowing for a more nuanced and detailed audio experience.

Moreover, the overall audio performance of the subwoofer is greatly enhanced through effective box bracing. It ensures that the sonic output of the subwoofer is actual to the source material, providing an audio experience that is both immersive and authentic. Listeners can expect a noticeable difference in the sound’s clarity and fidelity, with reduced muddiness or distortion often caused by uncontrolled vibrations.

In summary, the practice of box bracing is an indispensable element in the design of a high-performing subwoofer box. It requires careful consideration and execution but yields significant rewards in improved sound quality, enhanced bass response, and superior overall audio performance. It’s a critical step that, when executed correctly, can transform a good subwoofer box into an exceptional one.

Impact of Box Bracing on Sound Quality

When subwoofer box walls flex, resonance occurs, resulting in muddied, distorted bass. Box bracing helps minimize box vibrations, producing cleaner, tighter lows and enhancing audio clarity. Adding braces to subwoofer box walls can achieve accurate bass reproduction, improving sound quality and creating a more immersive audio experience.

The Role of Box Bracing in Reducing Vibrations

Unwanted vibrations and resonance within a subwoofer box can harm audio quality, leading to distortion, rattling, and muffled bass response. These problems arise when the enclosure walls of the subwoofer box vibrate excessively, which can significantly degrade the sound output. To combat these issues, box bracing plays a pivotal role. Incorporating well-designed braces into the box’s structure can substantially reduce internal vibrations.

Reducing vibrations is crucial in minimizing resonance and preventing vibration-induced audio complications that can impair the listening experience. The effectiveness of box bracing is seen in its ability to dampen the enclosure walls. This damping process ensures the bass output remains clean and distortion-free. A well-braced box can effectively absorb and dissipate the energy that would otherwise cause the walls to vibrate, thus maintaining the clarity of the sound produced.

Furthermore, box bracing contributes to isolating the internal volume of the subwoofer box. This isolation is vital to preserving audio fidelity, as it prevents external noises and disturbances from infiltrating the box and affecting the sound quality. In summary, one can achieve a more stable and acoustically sound subwoofer box through strategic bracing. This stability enhances the audio performance and provides a more enjoyable and immersive listening experience. The listeners can appreciate the depth and clarity of the bass without the interference of unwanted vibrations and resonances, leading to a more satisfying and enriched audio journey.

Critical Components of a Subwoofer Box Brace

When constructing a subwoofer box, paying close attention to several key elements essential for effective bracing is crucial. This includes thoroughly selecting the materials used in the box’s construction, mainly focusing on those that contribute to its structural integrity. Additionally, the design of the braces themselves plays a pivotal role. It’s not just about their placement or size but also about understanding each brace’s role in enhancing the subwoofer box’s overall sound quality and durability. When carefully considered and implemented, these factors ensure that the subwoofer box delivers exceptional sound performance and stands the test of time.

Materials Used for Box Bracing

In the construction of box bracing, various materials are typically employed, each chosen for its specific properties and contribution to the overall performance of the box. Wood, known for its natural resilience and strength, is widespread. Plywood, with its layers providing additional stability and resistance to warping, is another favored material. MDF (Medium-density fiberboard) is also commonly used due to its uniform density and smooth surface, which are ideal for achieving precise dimensions and shapes.

A particle board designed to resist vibrations is often selected for the internal braces. This type of particle board is vital in ensuring rigidity and stability within the structure, which is crucial for maintaining the integrity of the sound produced. The role of these internal braces is to reinforce the box, preventing unwanted vibrations that can distort audio quality. In addition to the choice of material, using quality wood glue is paramount in securing the braces effectively. This glue provides a long-lasting bond that is essential for the durability of the box, ensuring that it remains intact and functional over long periods of usage.

The selection of bracing material is not arbitrary but is carefully considered based on various factors. These include the size of the box, the specifications of the woofer it is designed to house, and the desired audio performance. Each factor plays a critical role in determining the most suitable materials for box bracing, ensuring that the final product meets and exceeds sound quality and longevity expectations.

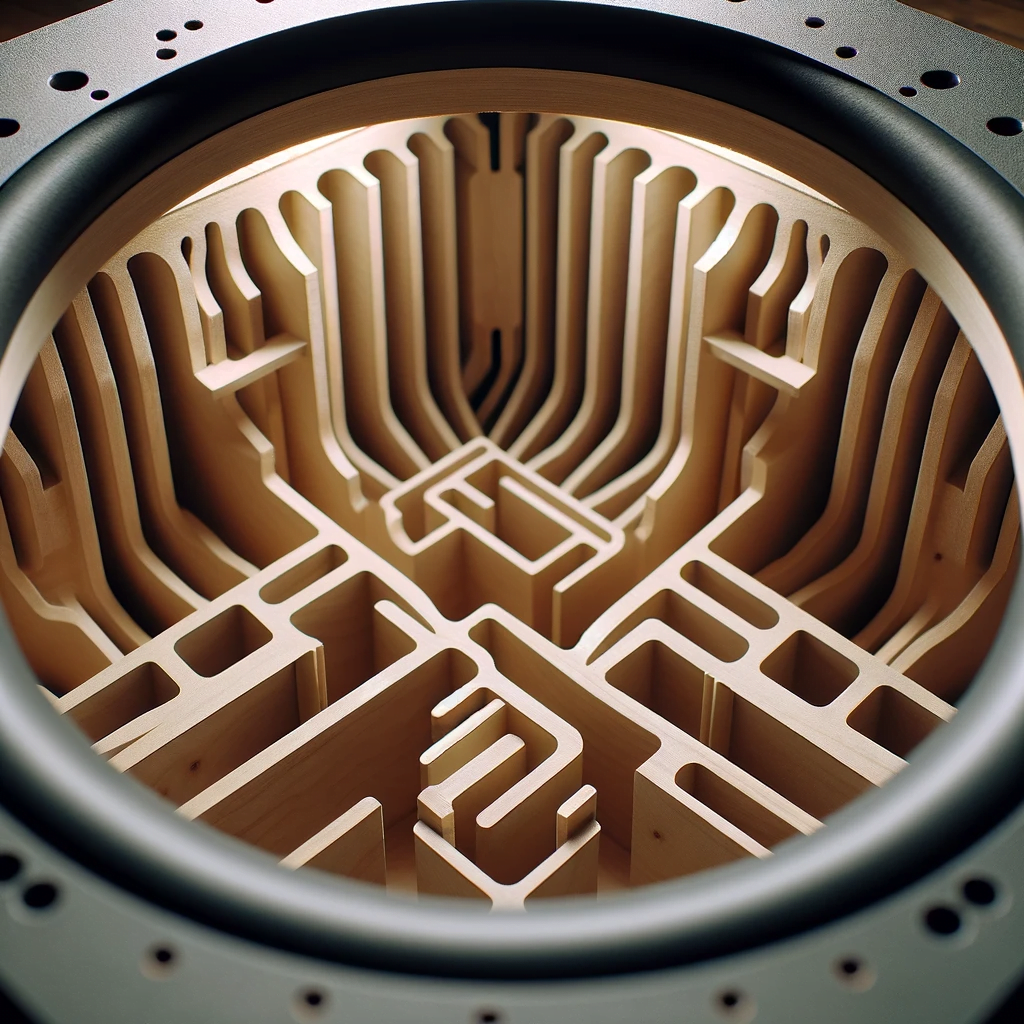

Designing an Effective Box Brace

Designing an effective box brace for a subwoofer encompasses a range of critical considerations, all aimed at achieving the highest level of audio performance. Initially, one must consider the specific dimensions of the subwoofer box, as these measurements are fundamental in determining the size and placement of the braces. Additionally, the woofer’s specifications play a significant role in this process, influencing the design to ensure compatibility and enhanced sound quality.

Furthermore, the design of the brace should be such that it makes efficient use of the enclosure’s internal volume. This efficiency is critical to maximizing bass output, allowing for a deeper, resonant sound. The strategic placement of the brace within the box is also crucial. It should be positioned in areas most prone to flexing, resonance, and vibration. Typically, these are the panel corners or larger surface areas of the box, which are more susceptible to these issues. Effective box bracing is not just about placement but also involves precise calculations to ensure that the brace aligns perfectly with the box’s acoustics. These calculations help in fine-tuning the brace for optimal performance.

The internal bracing must also be executed with meticulous attention to detail. The proper attachment techniques are essential for securing the brace in place, as a firm and stable brace contributes significantly to the overall sound integrity of the subwoofer box. Designing an effective box brace is a delicate balance of scientific calculations, careful material selection, strategic placement, and skilled craftsmanship. When all these elements come together, they ensure that the subwoofer box performs at its best and provides a consistently high-quality audio experience.

Step-by-Step Guide to Adding Braces to a Subwoofer Box

Now, let’s delve into the detailed process of adding braces to a subwoofer box. First, it’s essential to prepare by gathering all the necessary tools and materials for a successful bracing project. This preparation phase is crucial as it establishes a smooth and efficient workflow.

Ensure you have a comprehensive list of everything required, from the specific type of wood or other materials you’ll use for the braces to the tools like saws, drills, and measuring instruments. It’s also essential to have high-quality wood glue and fasteners to ensure a secure and durable build. Having all these items ready and at your disposal, you can proceed confidently, knowing you’re fully equipped to reinforce your subwoofer box with precision and expertise.

Tools Required for the Process

To add braces to your subwoofer box, you will need:

- Wood glue: For robust and durable brace attachments.

- Clamps: To hold braces in place while glue dries, ensuring proper bonding.

- Wood screws or dowels: To secure braces to subwoofer box walls, providing rigidity and stability.

- Measuring tape, ruler, or square: For precise brace placement, ensuring optimal audio performance.

- Screwdriver, drill, or appropriate tools: Ensure a secure fit for brace installation.

Preparing the Subwoofer Box

Before adding braces, it is essential to prepare the subwoofer box:

- Remove the subwoofer: Ensure the box is empty and free of internal obstructions.

- Clean the box: Remove any dust, debris, or loose particles from the box.

- Inspect the box: Check for any damage, addressing any necessary repairs before bracing.

- Measure box dimensions: Determine internal volume and brace placement areas, aiding in brace design and installation.

Installing the Brace

Now, let’s proceed with installing the brace in your subwoofer box:

- Apply wood glue: Apply wood glue to brace surfaces, ensuring even coverage.

- Position the brace: Place the brace in the desired location, aligning it properly with subwoofer box walls.

- Secure the brace: Use wood screws, dowels, or other attachments to ensure a tight fit.

- Use clamps: While glue dries, use clamps to hold braces in place, promoting proper bonding.

- Allow drying time: Allow sufficient drying time before reassembling the subwoofer box, ensuring a robust and stable brace.

What are the Common Mistakes to Avoid While Bracing a Subwoofer Box?

While bracing a subwoofer box, there are common mistakes to avoid to ensure optimal audio performance and longevity of your bracing project:

- Avoid using particle board: Particle board lacks rigidity, leading to panel resonance and compromised audio quality.

- Don’t skimp on internal bracing: Sufficient internal bracing reduces vibration, flexing, and resonance of enclosure walls, enhancing audio clarity and bass response.

- Use wood glue and dowel attachments: Wood glue provides a robust and durable bond, while dowel attachments add rigidity, ensuring bracing stability.

- Don’t overlook damping materials: Damping materials, such as foam or damping pads, help minimize bass resonance, enhancing audio quality.

- Avoid using scrap plywood pieces: Scrap plywood may not provide sufficient internal volume, compromising audio performance. Opt for appropriately sized braces for optimal results.

Conclusion

In conclusion, subwoofer box bracing is crucial in achieving optimal sound quality and reducing unwanted vibrations. By understanding the impact of box bracing on sound reproduction, you can enhance your audio experience and make the most out of your subwoofer system. The key components and materials used for box bracing must be carefully considered, and the design should be tailored to your specific needs. Following a step-by-step guide and avoiding common mistakes will ensure your subwoofer box is adequately braced. To learn more about advanced techniques for improving sound in your car audio system, check out our blog on advanced subwoofer enclosure designs.