Table of Contents

Introduction

Piezo speakers, also referred to as piezoelectric speakers, piezo loudspeakers, piezo buzzers, and piezo tweeters, are audio devices that leverage the extraordinary characteristics of piezoelectric materials to create sound. In contrast to traditional electrodynamic or electrostatic loudspeakers that depend on electromagnetic and electrostatic principles, piezo speakers harness the piezoelectric effect to transform electrical energy into mechanical vibrations, thereby generating sound waves. This distinctive technology presents a multitude of advantages and applications, making piezo speakers an intriguing topic to delve into.

How Piezo Speakers Work

Brief Overview of Piezo Technology and its Origins

The foundation of piezo speaker technology lies in the field of piezoelectricity, which was discovered by the Curie brothers, Pierre and Jacques, in the late 19th century. They observed that certain crystals, such as quartz and tourmaline, generate an electric charge when subjected to mechanical stress. This phenomenon, known as the piezoelectric effect (derived from the Greek word “piezein” meaning “squeeze”), intrigued scientists and paved the way for numerous technological advancements.

Over the years, advancements in materials science and engineering techniques have led to the development of highly efficient and compact piezo speakers. These devices have found applications in various industries, including consumer electronics, automotive, aerospace, and medical devices. In the following section, we will delve into the inner workings of piezo speakers and understand how they transform electrical signals into audible sound.

Explanation of the Piezoelectric Effect

At the core of piezo speaker technology lies the piezoelectric effect, where certain materials exhibit the ability to generate an electric charge when subjected to mechanical stress or deformation. This effect is due to the unique crystal structure of piezoelectric materials, which enables the displacement of positive and negative charges within the material when subjected to an external force. This principle forms the basis for many piezo devices such as piezo force sensors, vibration sensors (accelerometers), and piezo energy harvesters.

It also functions in reverse. When an electric field (voltage) is applied to the piezo material, it induces deformation in the material. This principle is utilized in various devices, including piezoelectric actuators, piezo transducers, and piezo speakers. The electric field can be either direct current (DC) or alternating current (AC). When an AC voltage is applied to a piezoelectric material, it causes the material to vibrate at the same frequency as the electrical signal. These vibrations propagate through the material and are transmitted to the surrounding medium as sound waves, resulting in audible sound. Piezo material possesses a high electrical-to-mechanical energy conversion ratio, making piezo devices, such as piezo actuators and transducers, highly efficient. The unique capability to directly convert electrical energy into mechanical vibrations sets piezo speakers apart from their electromagnetic counterparts.

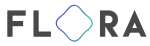

Description of the Components and Structure of a Piezo Speaker

A piezo speaker typically comprises essential components that play vital roles in its functionality. The primary component is the piezoelectric element, typically a thin disc or plate made of materials like lead zirconate titanate (PZT) or polyvinylidene fluoride (PVDF). The piezoelectric element attaches to an inactive layer (substrate) using adhesive, such as epoxy. When an alternative electric field passes through the piezo layer, it causes expansion or contraction within the plane. However, the substrate constrains this movement, resulting in the structure’s out-of-plane deflection. This cyclic deflection generates sound pressure that radiates into the surrounding air, producing audible sound.

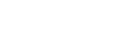

To enhance sound efficiency and directionality, a radiating surface, such as a paper cone or thin flat panel, is typically attached to the piezo speaker. This radiating surface, larger in size compared to the speaker itself, effectively amplifies the generated sound. Furthermore, a protective housing or enclosure is utilized to safeguard the internal components and provide structural support. This housing preserves the integrity of the piezo speaker, shielding it from external elements like moisture, dust, and mechanical shocks. Additionally, to optimize amplification and directionality, an acoustic horn is often incorporated to further refine the sound projection.

How to design a piezo speaker

Designing a high-quality piezo speaker requires careful consideration of both material selection and structural optimization. The choice of piezoelectric material plays a crucial role, with the displacement/electromechanical coefficient d31 being a critical parameter. This coefficient indicates the material’s ability to generate mechanical strain or deformation in response to an electric field. The specific value of d31 varies depending on the type and composition of the piezoelectric material.

For speaker applications, achieving a high sound pressure level is important. Therefore, selecting a soft PZT material with a high d31 coefficient, such as PZT-5H where d31 could reach 350 m/V x 10-12 range, is an optimal choice. Additionally, the adhesive material used should have a high modulus (>4GPa) to maximize the mechanical coupling between the piezo and substrate layers. It’s also important to choose a thermally stable adhesive with a high glass transition temperature (Tg) to ensure stable performance and increase the operating temperature range of the speaker.

The substrate material should possess sufficient rigidity and thermal stability. Common options include aluminum, brass, steel, and fiber composites (e.g., carbon, Kevlar fiber). While minimizing the thickness of the adhesive layer (10-20 um) is desirable, careful optimization of the thicknesses of the piezo and substrate layers is necessary. This optimization is typically achieved using techniques like Finite Element Method (FEM) simulation and design of experiments (DOEs).

By harnessing the piezoelectric effect and optimizing the design of these components, piezoelectric speakers offer unique advantages and capabilities compared to traditional electromagnetic speakers. In the following sections, we will delve into the differences between piezoelectric speakers and regular speakers and explore the fascinating applications of piezo speaker technology.

Powering Piezo Speakers

Piezo speakers necessitate an amplified audio signal to produce sound. Due to the capacitor-like behavior of the piezo material, they typically demand higher voltage and lower current and power, particularly at lower frequencies, when compared to electrodynamic speakers. Typically consuming less than 1W, piezoelectric speakers may require up to 100 V peak-to-peak, depending on the thickness of the piezo layer employed. While switching amplifiers, like class D and E amplifiers, are not compatible with piezo speakers, there are many commercially available regular audio amplifiers, such as class A, B, AB, or their variants, that can drive piezo speakers.

Given the high voltage requirement, an amplifier with 20-40x amplification is ideal. Additionally, low distortion and a high slew rate within the operating frequency range of 20-20 kHz are necessary. As there isn’t a specific amplifier designed exclusively for piezoelectric speakers on the market, considering a custom solution is advisable.

The Difference Between Piezo Speakers and Regular Speakers

Piezo speakers differ from regular electromagnetic speakers in several ways. One significant distinction is the method of sound generation. While regular speakers use electromagnetic principles to move a diaphragm and create sound, piezo speakers rely on the piezoelectric effect to generate vibrations directly in the piezoelectric material. This direct conversion of electrical energy into mechanical vibrations results in faster response times and improved efficiency.

Another difference lies in the frequency response and sound reproduction. Piezoelectric speakers excel at reproducing high-frequency sounds with great clarity and accuracy. This is due to the fact that with piezo speakers the radiating surface (cone) is directly attached to the vibration source (the piezo element or substrate), while with electrodynamic speakers the mechanical connection between the voice coil and the magnet (the spider) is very compliant. Their ability to handle high-frequency ranges makes them suitable for applications that require detailed audio reproduction, such as in tweeters or high-frequency drivers. On the other hand, regular speakers, with their electromagnetic drivers, often excel in reproducing mid-range and low-frequency sounds.

Piezoelectric Tweeters: Delivering Crisp High-Frequency Sound

Piezoelectric tweeters are a specialized type of piezoelectric speaker specifically engineered to reproduce high-frequency sounds, particularly in the upper range of the audio spectrum. Leveraging the unique properties of piezoelectric materials, these tweeters deliver crisp and detailed sound reproduction, capturing subtle nuances and intricate details that may be overlooked by other speaker technologies. However, it is worth noting that finding high-quality piezo tweeters can be challenging in the current market, as many available options suffer from poor quality control. Nevertheless, notable examples of well-designed piezo tweeters, such as the ones originally developed by Motorola, do exist.

These piezoelectric tweeters find widespread use in various audio systems, serving both professional audio setups and home entertainment environments. Their exceptional capability to handle high frequencies with precision and clarity makes them a favored choice among audiophiles and sound enthusiasts. It is common practice for speaker systems to incorporate different types of speakers, including piezoelectric tweeters, to effectively cover the entire audio spectrum and deliver an immersive listening experience.

Applications of Piezo Speakers

Versatile Applications of Piezo Speakers

Piezo speakers have a limited frequency range, which makes them less suitable for standalone loudspeaker applications. However, they excel in specific roles, particularly as buzzers, where their unique characteristics are advantageous. Here are some common applications of piezo speakers/buzzers:

- Alarm Systems: Providing audible alerts in security, fire, and industrial safety systems.

- Consumer Electronics: Generating sound alerts in clocks, watches, toys, and home appliances.

- Medical Devices: Auditory indicators in alarms, patient monitoring equipment, and medical instruments.

- Automotive Applications: Warning signals for seatbelt reminders, key-in-ignition alerts, and low fuel indicators.

- Communication Devices: Audible notifications and call alerts in telephones and intercom systems.

- Home and Office Appliances: Audio cues or feedback in printers, scanners, copiers, and vending machines.

Invisible Speakers: Blending Audio and Aesthetics

Invisible speakers, also known as flat panel speakers or flat wall speakers, are a modern application of piezo speaker technology. Novel piezo speakers, such as the Dragonfly™, are designed to be mounted behind walls or flat surfaces, seamlessly integrating with the environment without compromising audio quality.

By using piezo speaker technology, invisible speakers can transform surfaces like walls, ceilings, or even transparent materials into sound radiators. This approach eliminates the need for visible speaker grilles or bulky speaker cabinets, offering a clean and aesthetically pleasing audio solution.

Invisible speakers can be used in applications where architectural integration and spatial aesthetics are crucial, such as automotive, aerospace, home theaters, museums, art galleries, and retail spaces.

Pros and Cons of Piezo Speakers

Pros of Piezo Speakers

- Efficient Energy Conversion: Piezo speakers excel at converting electrical energy directly into mechanical vibrations, resulting in remarkable energy efficiency and reduced power consumption. Some piezo materials have an electromechanical coupling factor that can reach the range of 70%, which is significantly higher than the typical coupling factor of less than 15% in electromagnetic actuators. This high efficiency makes piezo speakers particularly well-suited for battery-powered applications, such as electric vehicles (EVs) and portable speakers, where maximizing energy utilization is essential.

- Compact and Lightweight: Piezoelectric speakers offer the advantage of being compact and lightweight compared to conventional speakers. Their thin form factor and reduced weight make them an excellent choice for applications with limited space or weight constraints, enabling seamless integration into various devices and systems.

- Full Range Frequency Reproduction: Innovative and well-designed piezo speakers surpass expectations not only in reproducing high-frequency sounds but also in delivering full range audio output with exceptional transparency and precision. As a result, these advanced piezo speakers have the capability to replace separate woofer, midrange, and tweeter speakers, streamlining the audio system and enhancing overall performance.

Cons of Piezo Speakers

- Limited Low-Frequency Response: Piezo speakers generally have limitations in reproducing low-frequency sounds due to their low displacement capability. To achieve a balanced audio spectrum, they are often paired with other speakers. However, newer generation piezo speakers, have been developed to address this limitation and provide improved low-frequency performance.

- Narrow Dispersion Pattern: Piezo speakers typically exhibit a narrower dispersion pattern compared to regular speakers, resulting in more focused sound projection in a specific direction, known as beaming. This characteristic is particularly noticeable at high frequencies (>3 kHz). To overcome this, multiple piezoelectric speakers are often arranged on a loudspeaker. Moreover, the use of flat panel piezo speakers can help alleviate this issue by providing better directivity and wider dispersion.

- High Voltages: Piezo speakers generally require high voltages to achieve the desired electric field for optimal performance. Amplifiers need to be designed accordingly to provide the necessary voltage. However, the high voltage requirement can be addressed by employing multi-layer piezo technology, which utilizes multiple thin piezo layers instead of a single thick layer. This approach helps mitigate the high voltage issue and facilitates the operation of piezo speakers.

How Piezo Speakers Sound

Conventional piezo speakers typically exhibit limitations in terms of sound pressure level (SPL) and frequency response, particularly at low frequencies below 800 Hz. As a result, they often produce harsh and low-quality sound. However, recent advancements in full-range flat panel piezo speakers have addressed these issues. These innovative speakers offer sound quality comparable to regular electrodynamic loudspeakers, with adequate frequency response at low frequencies. In addition, they deliver superior transparency, clarity, and directivity compared to traditional electrodynamic counterparts.

Regular piezo speaker

Full range flat panel piezo speaker

Conclusion

Piezo speakers, driven by the principles of piezoelectricity, offer a unique and efficient approach to sound reproduction. With their ability to convert electrical energy directly into mechanical vibrations, piezo speakers have found applications in a wide range of industries, including consumer electronics, automotive, aerospace, and medical devices.

From delivering crisp high-frequency sound through piezoelectric tweeters to blending audio seamlessly with architecture through invisible speakers, piezo speaker technology continues to push the boundaries of audio innovation.

While piezo speakers have their strengths in efficiency, compactness, and high-frequency reproduction, they may have limitations in low-frequency response and dispersion patterns. However, when used in combination with other speaker types, they can create immersive audio experiences that cater to a variety of applications.

As technology advances and new materials are discovered, the potential for piezo speaker technology to further revolutionize audio solutions remains promising. Whether it’s enhancing the audio quality of flat-screen TVs or powering the next generation of portable devices, piezo speakers continue to captivate the imaginations of hardware designers and audio enthusiasts alike.